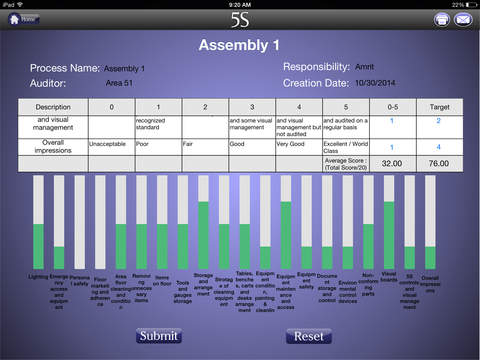

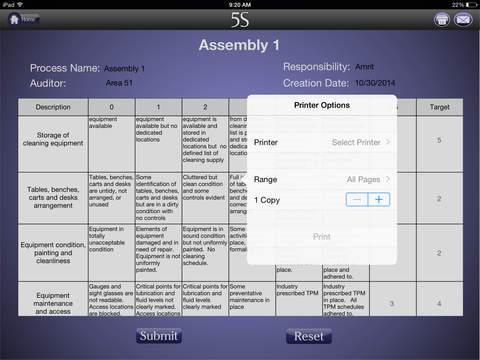

5S app for iPhone and iPad

Developer: Lean System Implementation LLC

First release : 09 Dec 2014

App size: 10.34 Mb

Quickly create and compare your 5S scores with targets. Identify improvement opportunities and focus on waste elimination.

5S is a lean manufacturing tool which focus on eliminating waste by cleaning organizing and Putin a formal discipline in place to maintain the standards.

5S was developed in Japan and stands for the Japanese words

seiri (tidiness),

seiton (orderliness),

seiso (cleanliness),

seiketsu (standardization), and

shitsuke (discipline).

These words have been adopted to English to maintain "5S.”

It can be further explained as

Sort- Remove unnecessary items

Set - Customize to improve efficiency

Shine - Cleaning the work area, equipment and tools

Standardize - Creating a standard of work for are

Sustain - Ensuring 5S is improvements are sustained for long term. This typically is executed with tiered audits.

The 5S program focuses on having visual order, organization, cleanliness, standardization.